on demand clothing manufacturing

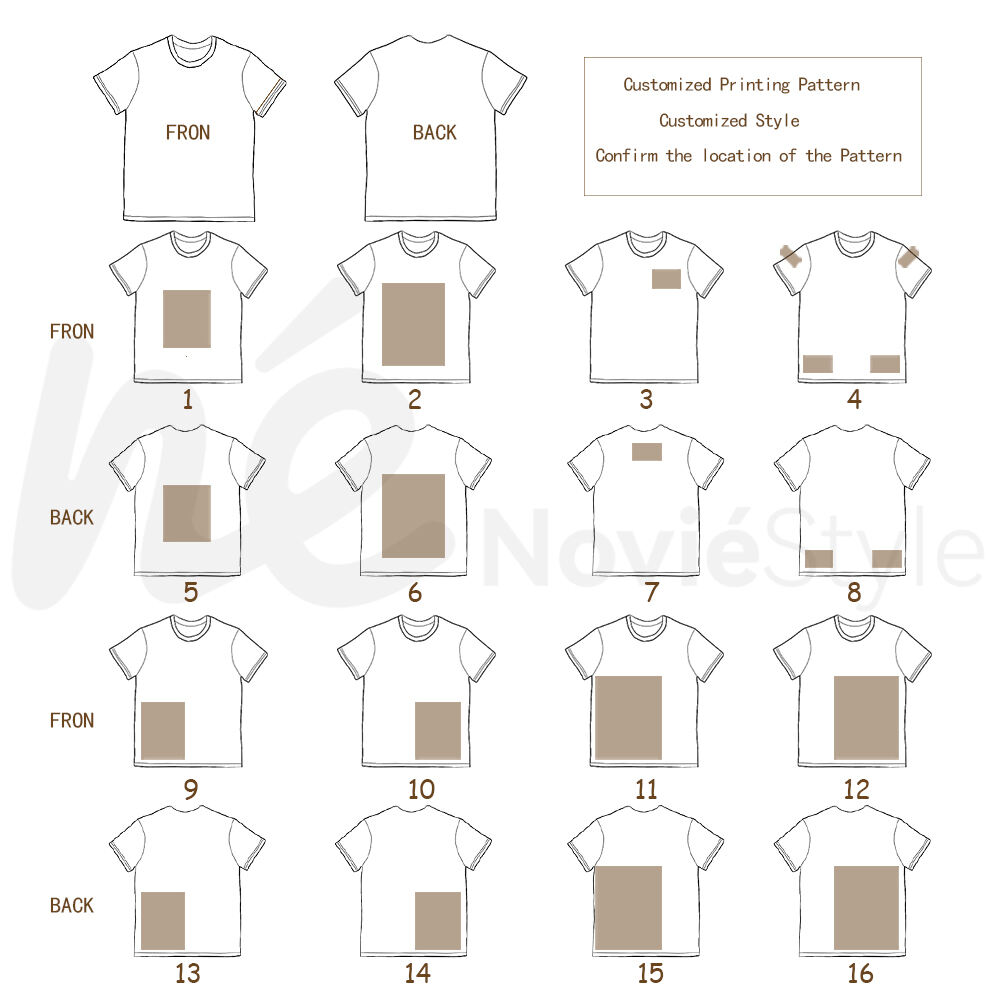

On demand clothing manufacturing represents a revolutionary approach to garment production that combines advanced technology, sustainable practices, and customer-centric solutions. This modern manufacturing method enables brands and designers to produce clothing items only when orders are placed, eliminating excess inventory and reducing waste. The process integrates digital design tools, automated cutting systems, and sophisticated production management software to streamline the entire manufacturing cycle. By leveraging cloud-based platforms, manufacturers can coordinate between design teams, production facilities, and quality control departments in real-time. The system employs precision machinery for pattern making, cutting, and assembly, ensuring consistent quality across all products. Advanced 3D visualization technology allows for accurate product representation before production begins, reducing sample waste and accelerating the development process. This manufacturing model particularly excels in customization capabilities, allowing for individual size adjustments, design modifications, and material selections based on customer preferences. The integration of artificial intelligence and machine learning algorithms helps optimize production schedules, resource allocation, and quality control processes, making the entire operation more efficient and cost-effective.